Company Profile

AIKO Group is a one-stop provider of high-end precision manufacturing services, specializing in wire harnesses, precision sheet metal, precision tubing, CNC machining, and precision assembly. Serving customers in home appliances, medical, aerospace, energy storage, and industrial equipment sectors, we are committed to becoming a trusted solution partner.

Group R&D Capability

Group R&D Capability

Wire Harness Processing Capability

Wire Harness Processing Capability

Sheet Metal Machining Capability

Sheet Metal Machining Capability

Aviation Component Processing Capability

Aviation Component Processing Capability

Assembly Capability

Assembly Capability

Surface Treatment Capability

Surface Treatment Capability

Who We Are

Delivering excellence in products and services to global customers.

Mission

To provide advanced solutions for high-end manufacturing through multi industry collaborative innovation.

Vision

Driving precision manufacturing and empowering upgrades across industries.

Values

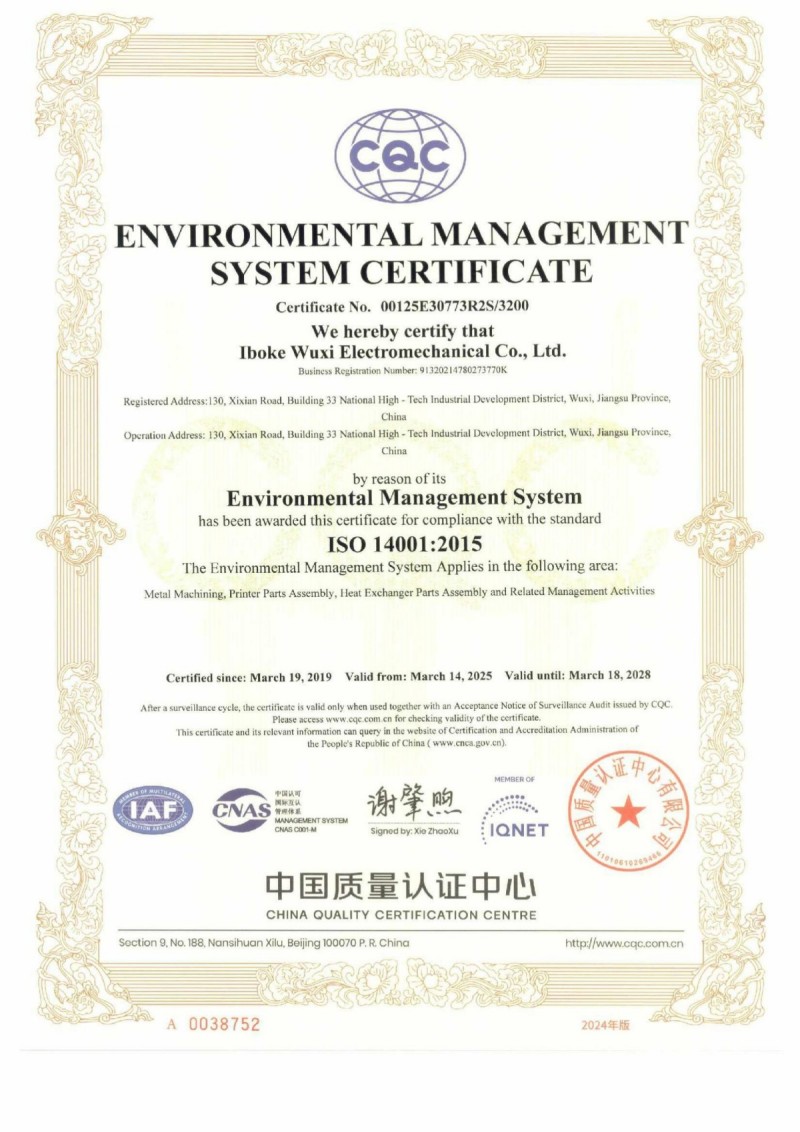

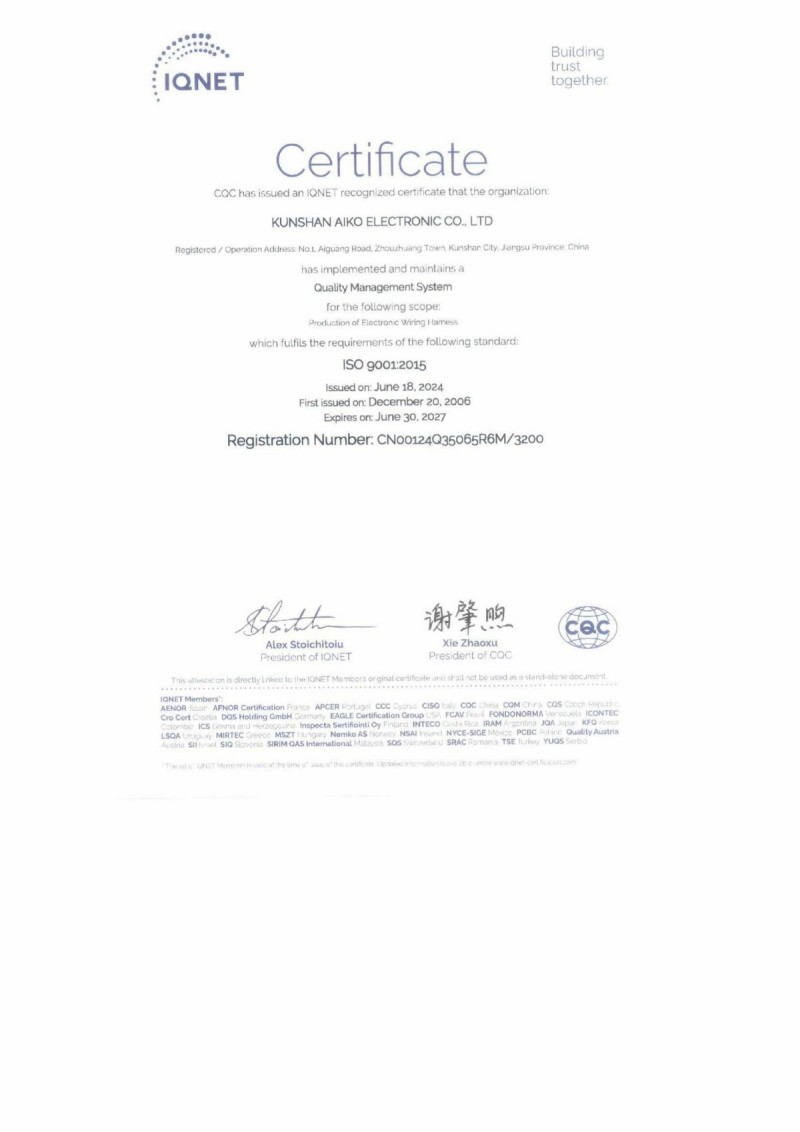

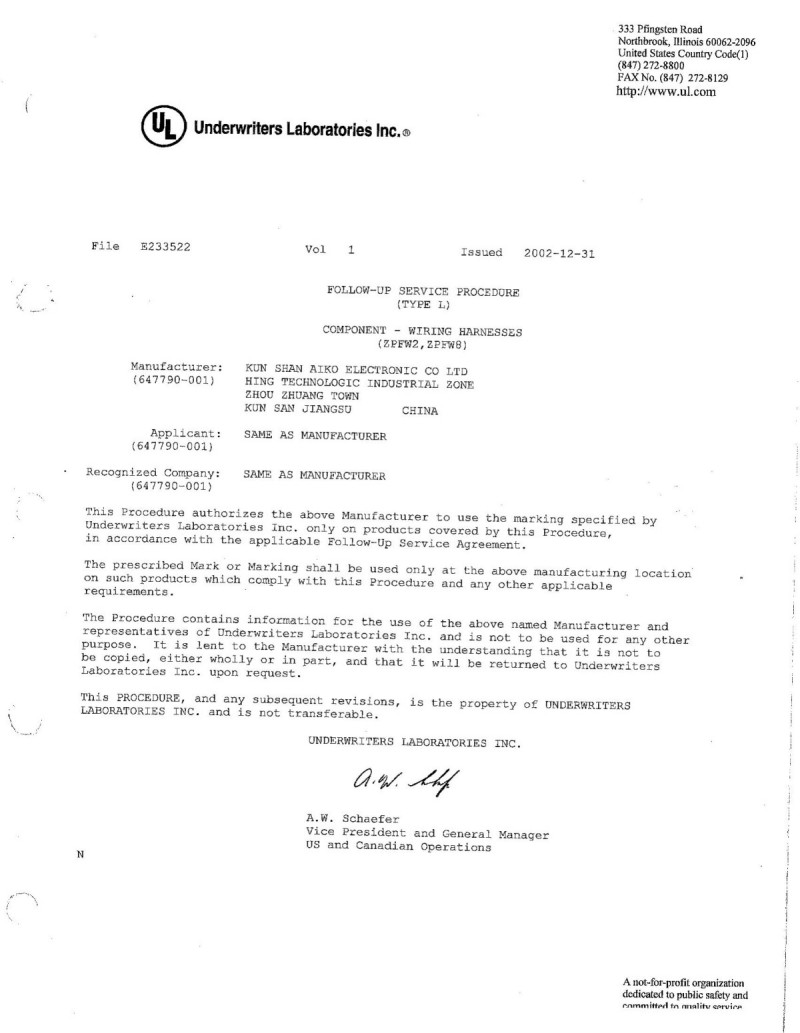

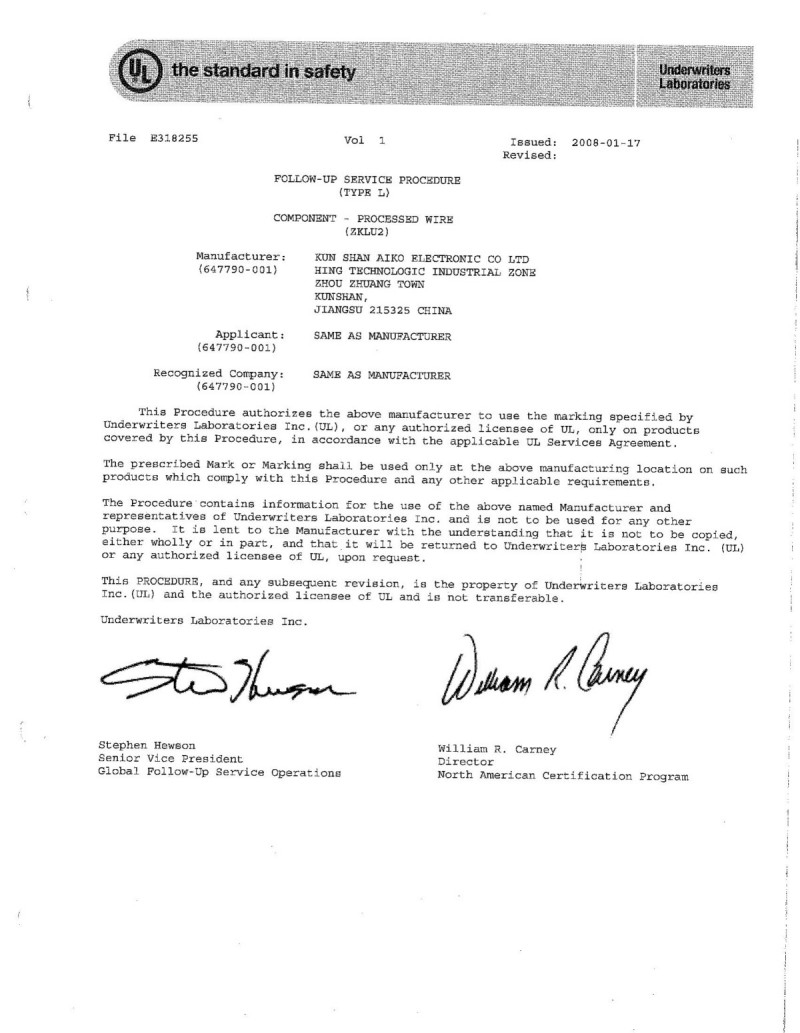

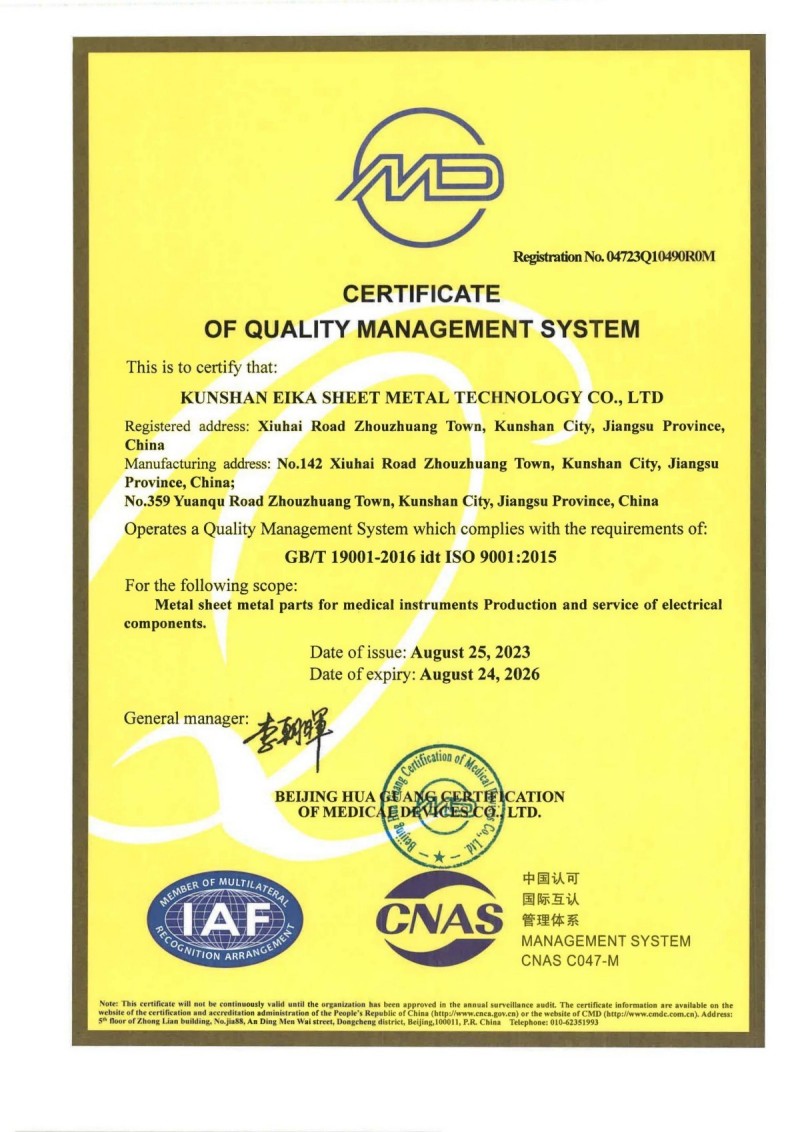

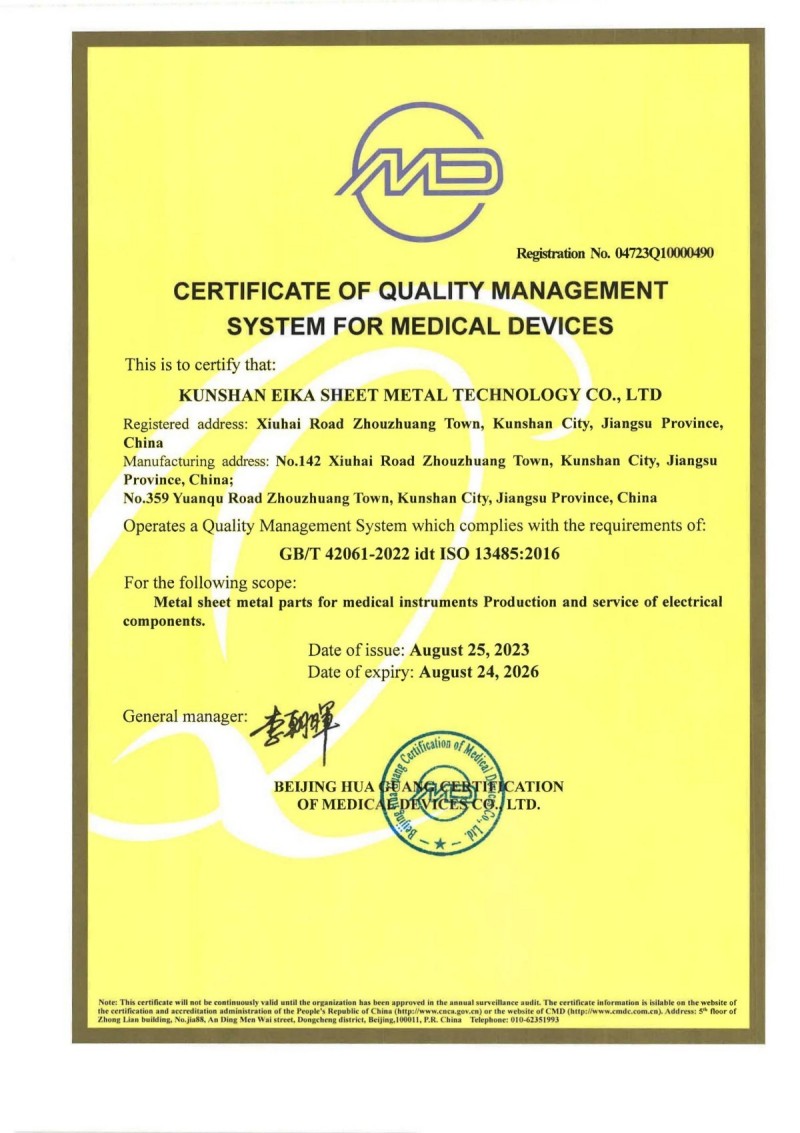

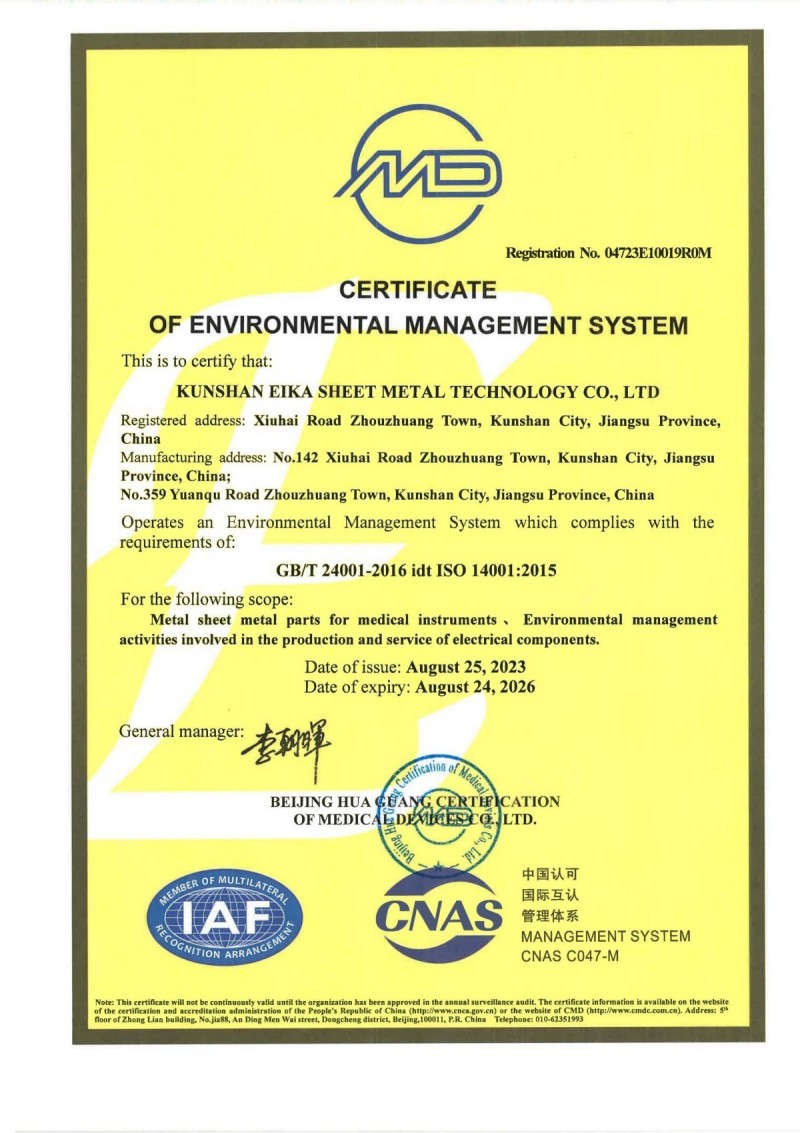

Integrity, quality, and win-win situation.System Certificate

Quick Response

Diversified Small-Scale Production

Provide High-Quality Customer Experience